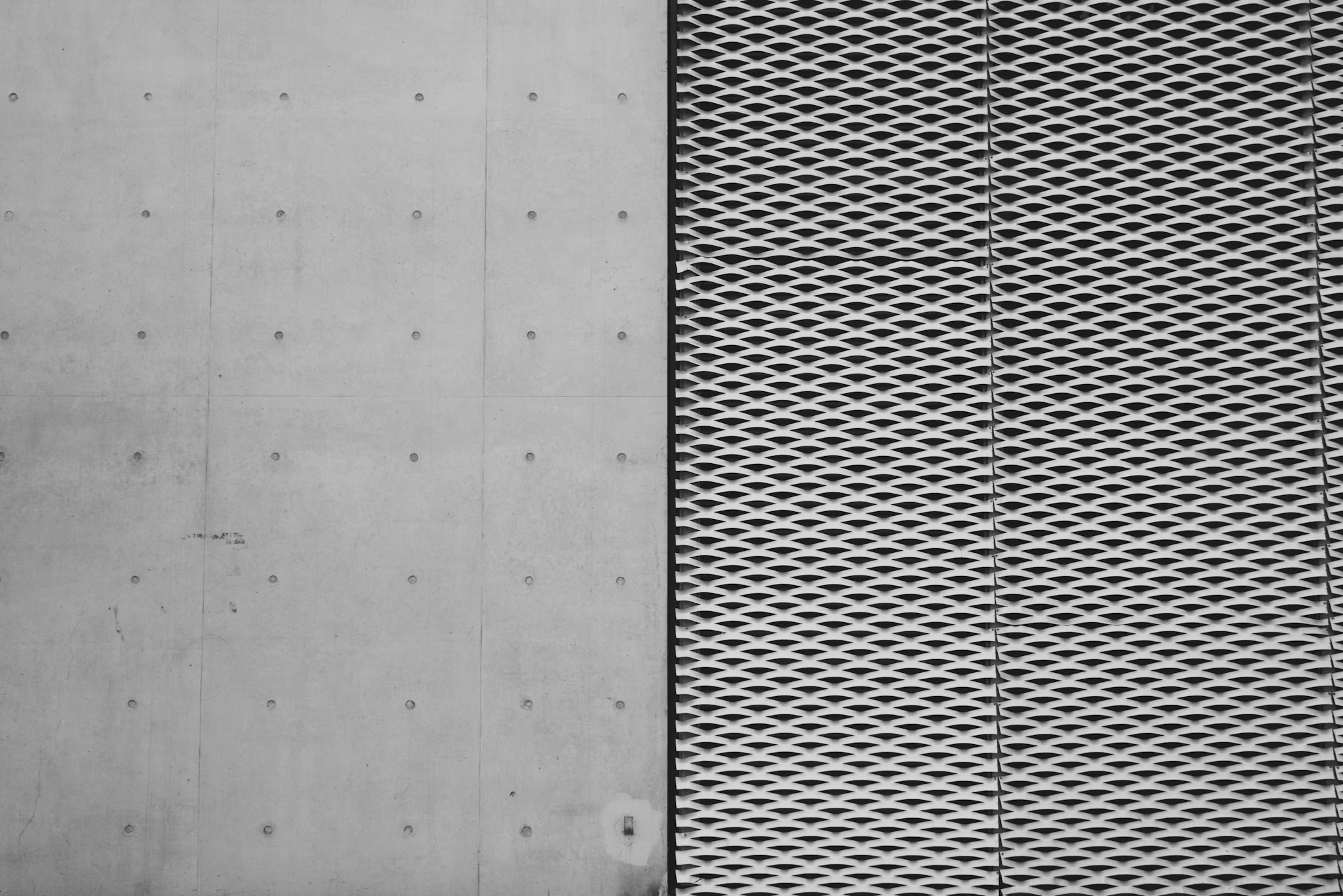

Stainless steel perforated sheets are versatile and durable materials, offering a multitude of benefits for a wide range of applications. Made from premium stainless steel, these sheets showcase impressive corrosion resistance, even in varying climatic conditions and when exposed to corrosive agents. Their high strength at high temperatures makes them an ideal choice for various uses, including decorative and functional purposes.

Perforated stainless steel sheets are fashioned with a variety of hole patterns, shapes, and sizes, making them highly customizable for diverse design needs. Not only do these unique sheets provide seclusion, but they also deliver aesthetically pleasing lighting effects. From interior and exterior design features to chemical and food-processing equipment, stainless steel perforated sheets are adaptable and innovative materials that suit numerous industries and projects.

Stainless steel perforated sheets offer versatility, durability, and corrosion resistance.

These sheets are used in a variety of applications, from decorative to functional purposes.

Customizable hole patterns and shapes make them adaptable for diverse design needs.

What Are Stainless Steel Perforated Sheets

Stainless steel perforated sheets from perforated metal sheet suppliers are a type of sheet made from stainless steel that has been stamped, punched, or cut to create patterns or openings. These sheets are widely used for both aesthetic and functional purposes, primarily because of their resistance to corrosion, durability, and versatility.

Production Process

The production process of stainless steel perforated sheets involves using a machine equipped with sharp cutting tools, or dies, to create the desired hole patterns. A stainless steel sheet is fed into the machine, and the dies apply pressure on the sheet to create a specific design or pattern. The final product contains holes of various shapes and sizes, depending on the intended application.

Properties

The key properties of stainless steel perforated sheets include:

Corrosion Resistance: Stainless steel, particularly grades like SS 304, SS 304L, SS 310, SS 316, SS 316L, SS 347, and SS 904L, offers exceptional resistance to corrosion. This makes it ideal for use in both interior and exterior applications, where it can handle exposure to various elements.

Strength and Durability: Despite its lightweight nature, perforated stainless steel is strong and durable, making it suitable for a wide range of applications and industries.

Flexibility in Design: Perforated stainless steel can be customized to suit specific requirements, with options for various hole shapes, sizes, patterns, and even custom designs. It can also be bent, shaped, or otherwise manipulated to fit specific applications.

Functional Benefits: The perforations allow for the passage of light, liquid, sound, and air, while offering a decorative or ornamental effect. This makes stainless steel perforated sheets suitable for purposes like ensuring privacy, providing aesthetic appeal, or enabling effective filtration and ventilation.

Uses of Stainless Steel Perforated Sheets

Construction Industry

Stainless steel perforated sheets are widely used in the construction industry due to their corrosion-resistant and durable properties. These sheets are commonly utilized for decorative purposes, such as architectural accents, as well as for functional reasons like ventilation. The passage of light, sound, and air provided by the perforations make them a popular choice for building facades and cladding.

Manufacturing Industries

In various manufacturing industries, perforated stainless steel sheets are employed for their high hardness and resistance to wear. Some common applications include:

Food processing: These sheets are an ideal choice for restaurant and food processing equipment, as they maintain their shape and are easy to clean.

Filtration: In industries requiring non-corrosive filters, perforated stainless steel sheets provide an excellent solution, offering durability and resistance to damage.

Automobile Sector

The automobile industry benefits from the use of perforated stainless steel sheets in numerous ways. These sheets are often found in:

Exhaust systems: Due to their heat resistance, perforated sheets are used in exhaust systems to improve airflow and reduce noise levels.

Grilles and vents: For both aesthetics and functionality, these sheets are used to create visually appealing grilles and vents that also help maintain the vehicle’s performance.

Aerospace Industry

In the aerospace industry, stainless steel perforated sheets serve a variety of purposes, including:

Weight reduction: Owing to their lightweight nature, these sheets can be used to reduce the overall weight of an aircraft, enhancing fuel efficiency.

Airflow management: The perforations in these sheets help facilitate airflow, making them an excellent choice for ventilation systems in aerospace applications.

Overall, stainless steel perforated sheets offer a wide range of applications in various industries, owing to their unique combination of aesthetics, durability, and functional properties.

Benefits of Using Stainless Steel Perforated Sheets

Durability

Stainless steel perforated sheets are known for their high strength-to-weight ratio, which allows for reduced material thickness while still maintaining durability. This results in considerable cost savings for applications where a thinner, lighter material is desired without compromising strength. Furthermore, stainless steel is capable of withstanding harsh weather conditions and extreme temperatures, making it a suitable option for both indoor and outdoor applications.

Corrosion Resistance

One of the main advantages of stainless steel perforated sheets is their resistance to corrosion. This makes them ideal for use in environments where they may be exposed to moisture, chemicals, or other corrosive substances. Stainless steel’s natural corrosion resistance helps to extend the life of the material, reducing the need for frequent replacements and minimizing maintenance costs. Examples of industries that benefit from corrosion-resistant stainless steel perforated sheets include the restaurant and medical industries.

Aesthetic Appeal

In addition to the practical benefits, stainless steel perforated sheets also offer a modern and visually appealing appearance. The perforations create unique patterns and designs that can enhance the overall look of a project, making them suitable for both functional and decorative purposes. The sheets can be used to diffuse light and sound, creating a balance between utility and aesthetics. This makes stainless steel perforated sheets ideal for applications like architectural design, interior decoration, and ornamental lighting effects.

Wrapping It Up

Stainless steel perforated sheets are versatile products created by punching or stamping various holes, shapes, and patterns into sheet metal. These sheets are made from a steel alloy containing at least 10.5% chromium and 0.25% nickel, giving it enhanced corrosion resistance and durability. The wide array of patterns and shapes available allows for customization to fit various project requirements and designs.

Applications of stainless steel perforated sheets span across both interior and exterior domains. They can be found in commercial and industrial settings, providing an elegant, functional, and practical solution. Some common uses include decorative panels, filtration systems, ventilation grilles, and as components in sound dampening systems.

In comparison with standard steel, stainless steel perforated sheets offer increased corrosion resistance and strength. They are an excellent choice for applications requiring a balance of strength, durability, and aesthetics. Moreover, their resistance to rusting ensures that they maintain a clean, polished appearance over time.